limitation on the thickness of specimens for a hardness test|hardness test spacing : online sales In hardness testing according to Rockwell, the total test force is applied in two . WEBPEN15. PEN15 is middle school as it really happened. Maya Erskine and Anna Konkle star in this adult comedy, playing versions of themselves as thirteen-year-old outcasts in the year 2000, surrounded by actual thirteen-year-olds, where the best day of your life can turn into your worst with the stroke of a gel pen.

{plog:ftitle_list}

web5 dias atrás · Você pode encontrar palpites de hoje para os mercados de 1x2, over/under, handicaps, cartões, escanteios e muito mais. Quer um exemplo? Para os prognósticos .

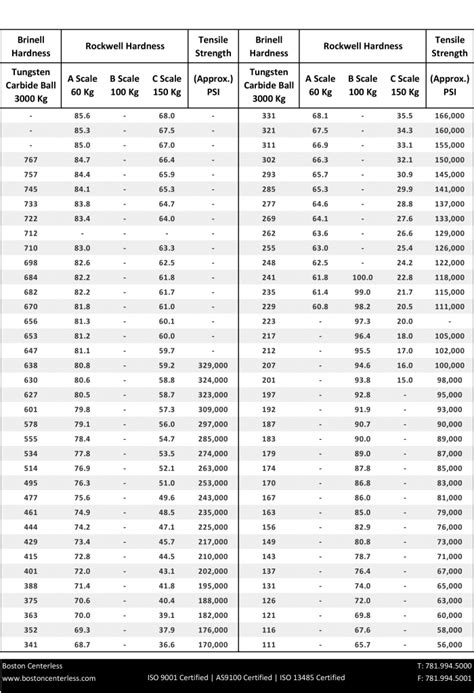

The specimen must be thick enough for the indent not to cause any visible deformation on the underside of the specimen (supporting surface). This means that, according to the standard, the specimen must be at least eight times thicker than the indentation depth of the Brinell ball.In hardness testing according to Rockwell, the total test force is applied in two .During specimen testing or coupon block verification, the spacing between indents, as well as from the material edge, must be properly maintained to prevent any adjacent indents or . Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the .

What is the limitation on the thickness of specimens for a hardness test? Explain. Calculate the minimum thickness for one specimen for the Rockwell test and one forIt is important to note that Brinell hardness testing may not be suitable for materials with very high hardness or thin and small components where a smaller indentation size is desired. In .

Limitation in applying the method on thin specimens of very hard materials (see Brinell method, minimum specimen thickness). The process is slow (by comparison with the Rockwell .In order to prevent the test base (e.g. the test anvil) from affecting the test result in any way, a minimum specimen thickness must be observed with the Brinell method (acc. to ISO 6506). This minimum specimen thickness must be eight .

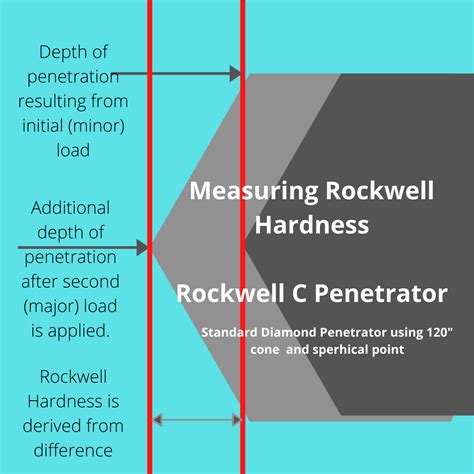

The factors concerned include hardness level (and scale limitations), specimen thickness, size and shape of the workpiece, specimen surface flatness and surface condition, and indent .A sample should have a minimal thickness that is at least ten times the indentation depth is expected to be attained. There are minimum thickness recommendations for regular and .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

All information about the Vickers hardness test Test procedure Sample request for the Vickers method Vickers hardness Hardness Discover now . This means that the size of indentation left by the indenter is measured to determine the .Learn about considerations, sample sizes, sample thickness, scales and hardness testing methods in this article about the hardness testing basics. . Case depth testing often involves performing a series of hardness impressions from the edge of the specimen towards the center. The hardness progression is plotted on a graph and the distance .A full range of accessories for hardness testing, including test blocks, specimen holders, clamps, indenters and lenses. . Sample thickness ASTM: At least 10 times the indentation depth; . The hardness progression is plotted in a graph .

Hardness testing is widely used in a multitude of . Specimen thickness Area / width Test location Material homogeneity Scale limitations Material Type In the absence of a specified hardness scale the material type should be identified and compared with various tables that list the typical type of scale The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.

Hardness testing is a vital process in many industries. . 10 and 2.5, which are selected according to the material hardness and sample thickness. See various standards and test specifications for details. Fig. 1-21 Application of similarity principle . metallographic specimens can be used to measure the hardness or hardness distribution of .

Additional CRMs near, or bounding, the hardness of the specimen(s) may be used during the procedure. 7 S. AMPLING . Whole components, or sections thereof, are typically presented to the indenter for hardness testing. Hardness readings should be interpreted to apply only to that material in the immediate vicinity of the indentation.The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is . an automatic hardness testing machine where the hardness is determined auto-matically. Depending on the size of the applied load, the indentation hardness test can be divided into macro (also called gen-eral or universal) and micro hardness testing. For macro hardness testing, the test loads are 1 kgf (9.81 N) or larger,

willrich hardness testing distance

Hardness testing is widely used in a multitude of . Specimen thickness Area / width Test location Material homogeneity Scale limitations . Material Type . In the absence of a specified hardness scale the material type should be identified and compared with various tables that list the typical type of scale

Since Rockwell hardness testing entails the measurement of depth, a stable and steady platform for executing the test is highly recommended for the precision and reliability of the actual results of the test. . Furthermore, material thickness also counts as a requirement, thereby allowing the determination of what indenter is appropriate for .Question: 2)What is the limitation on the thickness of specimens for a hardness test ? 2)What is the limitation on the thickness of specimens for a hardness test ? Here’s the best way to solve it. Solution.TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

the creep data for two different samples. You have been asked to analyse the results, if you know that the original length of specimen is 17.4625 mm and the original width is 4.8 mm and the original thickness 1.6 mm and the cross sectional area is 7.68 mm: 1.

Limitation in applying the method on thin specimens of very hard materials (see Brinell method, minimum specimen thickness). The process is rather slow (compared with the Rockwell method ). The test cycle takes somewhere .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find . 2.what is the limitation on the thickness of specimens for a hardness test ? Explain 3.What are the limitations for distance from specimen edge to indentation and distance between indentations? Explain why these limitations is exist in both cases.7. Test Specimens 7.1 The testing area shall be smooth and free from mechani-cal defects. 7.2 Dimensions—Test specimens shall be at least 1.5 mm [1⁄ 16 in.] thick and large enough to ensure a minimum distance of3mm[1⁄ 8 in.] in any direction from the indentor point to the edge of the specimen, as well as from test point to test point. 8.

2.Test step The additional test force is then applied for a dwell time (several seconds) defined according to the standard, whereby the indenter penetrates the specimen to the maximum penetration depth h1. The sum of the test preload and additional test force is the total test force (also referred to as total force or main load). 3.Test step Rockwell hardness test; Specially prepared specimens or real components can be used for hardness testing, provided that their functionality is not impaired due to the indentation left behind. . In principle, the sample thickness \(s\) should be at least 8 times the penetration depth \(h\): \begin{align} \label{mindestprobendicke}

The Rockwell Testing systems depend on the material that is being tested including the hardness, thickness, indentation positioning, and scale limitations on the materials that are being tested. The material being tested must be at least 10x thicker than the indentation that the Rockwell indentation is going to be when it is made of the material.

The hardness of the specimen is quickly read within one second of establishing firm contact. ASTM D2240 Test Specimens. . The test specimens typically have a thickness of 6.4 mm (¼ inch). ASTM D2240 Test Result. ASTM D2240 is a standard test method for determining the relative hardness of soft materials, commonly plastic or rubber. It is .What is a Brinell Hardness Test? Standards of Brinell Hardness Testing; Brinell Hardness Test Procedure. 1. Preparation of the Specimen; 2. Selection of Load and Indenter; 3. Test Machine Setup; 4. Load Application; 5. Indentation Measurement; 6. Calculation of Brinell Hardness Number; 7. Reporting the Results; Advantages and Limitations of the .

standards for hardness testing

The minimum thickness should be ten times the depth of the indentation. For Rockwell Hardness Scale C (HRC): Typically, the sample should be at least 0.6 to 1.0 mm thick. For Rockwell Hardness Scale B (HRB): Typically, the sample should be at least 0.8 to 1.6 mm thick. Strengths and Limitations of Rockwell Hardness Test

Test Scale Type of material Specimen thickness Area / width Test location Material homogeneity Scale limitations. Material Type In the absence of a specified hardness scale the material type should be identified and compared with various tables that list the typical type of scale that is applicable to a given material.The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520; [email protected] . Test Specimens – Another critical concern for an accurate test result is the specimen which must be clean and void of any surface impurities that might interfere with the reading. Though the Rockwell . 2.what is the limitation on the thickness of specimens for a hardness test ? Explain 3.What are the limitations for distance from specimen edge to indentation and distance between indentations? Explain why these limitations is exist in both cases.

web2 dias atrás · Most Recent. The Irrational - Watch episodes on NBC.com and the NBC App. Jesse L. Martin stars as a behavioral science professor solving tough cases.

limitation on the thickness of specimens for a hardness test|hardness test spacing